Reliable Water Jet Ejector Vacuum System – Needs Low Maintenance

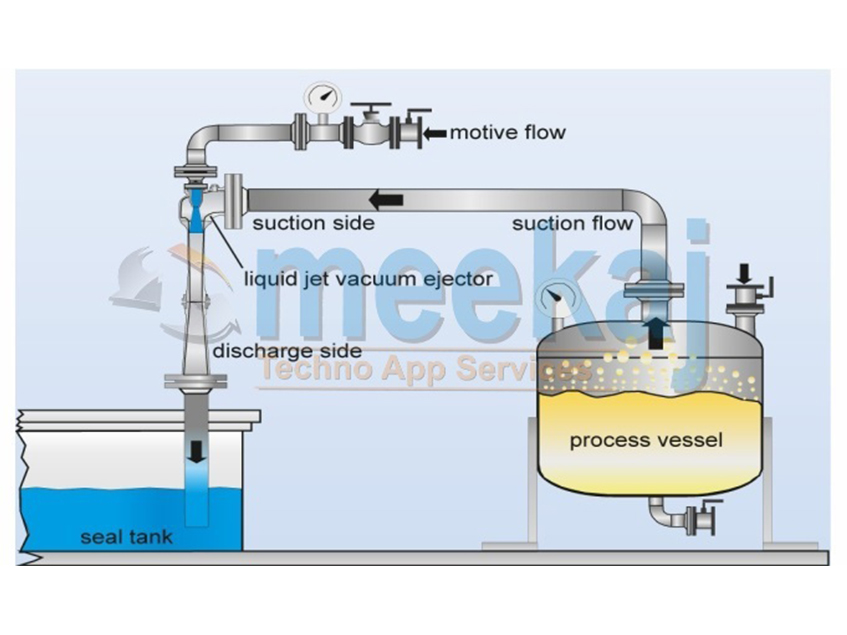

Water jet ejector vacuum system is typically built to work by high-pressure water, solvent or other clear liquids. These devices generate vacuum corresponding to the vapour pressure of the water or liquid. Meekaj Vacuum Systems Pvt Ltd. is a renowned water jet ejector supplier. We have clients from all over the world. Various industries constantly use our exclusive products because of their high reliability and low maintenance. Our water ejector vacuum system is excellent to aid industrial actions such as distillation and evaporation.

Importance Features of our Products

Water jet eductors are mainly used for liquid pumping and mixing operations. Water is the motive force in these devices. Kinetic energy is utilized to entertain gases and vapours. Being a reputed water jet ejectors manufacturer, our products reflect the features such as low maintenance cost, easy to operation options, easy to install and no extra cost for installation and simple and unique designs. Our water jet ejector vacuum system is reliable in operation under various conditions. There is no sound and ensures virtually silent operation. Our products are highly suitable for tough and hazardous working conditions. Call us today, and we can custom design and build your water ejector vacuum system.

Being one of the well-known vacuum equipment manufacturers, we have acquired a unique name for ourselves among the top brands across the world. You are in the right place to buy water jet editors required for your industry. Tell us your requirements, and we can meet it ensuring the highest possible quality.

Water ejectors are vacuum pumps, driven by a high pressure water (or similar medium) or steam. They use kinetic energy of the driving medium to suck in gases, vapours or other liquids and then discharge the resultant mixture against a counter pressure.

Turbine Works manufactures water ejectors for industrial and marine purposes.

Ejectors are simple in design and reliable in operation since they don’t have movable parts like standard pumps. Major parts of an ejector are a inlet casing, nozzle, mixing chamber and diffuser. Since there are no moving parts, no lubrication is necessary and maintenance is minimal. Ejectors are self-priming and easily activated by simply turning on the flow of the driving water.

Water ejectors depending on application can be manufactured out of various materials ranging from bronze, steel, stainless steel with nozzles usually being made out of hi grade stainless steel or monel.

EJECTOR DEFINING PARAMETERS:

Qs – Suction capacity

Hd – Delivery head

Hs – Suction lift

Qd – Driving medium consumption

Pd – Driving medium pressure at ejector inlet

MARINE WATER EJECTORS

Due to their excellent suction capability and reliability, water ejectors are frequently used for marine applications such as:

Ballast stripping ejector

Bilge stripping ejector

Chain locker ejector

Sewage (black) water vacuum suction

Misc. other applications

Their above applications and size which can vary from 50 cm to more than few meters, make them significant part of ship’s engine room equipment.

Below is the table with TTK standard water ejectors and their most typical driving parameters. Please contact us for your exact requirements.